Selective Li Extraction via Material Engineering and Surface Treatment

Enhancing lithium extraction performance through material engineering and process modeling.

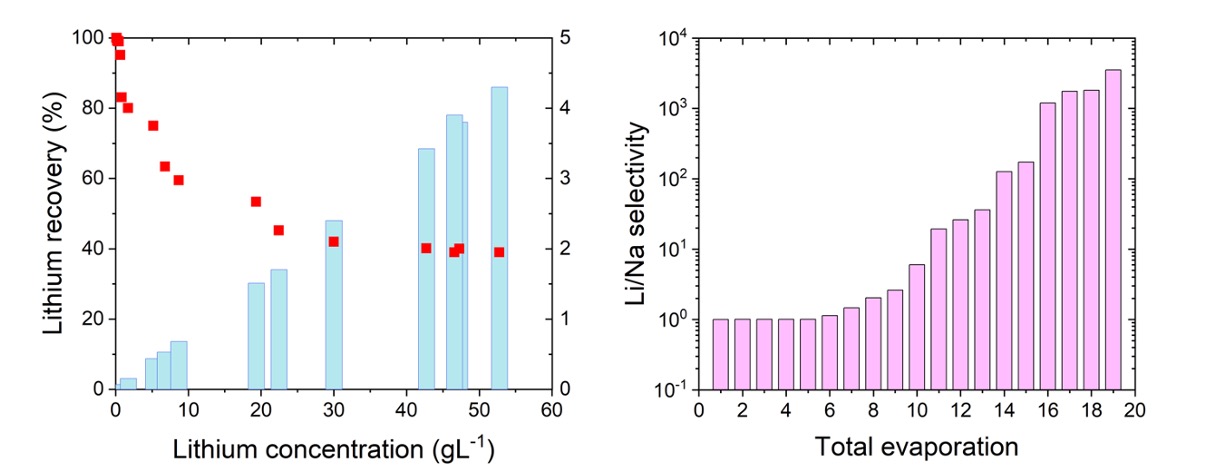

Lithium is a critical mineral with a rapidly growing global market, and oil field brines are recognized as potential game changers for lithium supply. However, current extraction techniques, such as evaporation ponds and direct lithium extraction methods, face challenges with low lithium concentrations and limited selectivity between lithium and other monovalent ions, making lithium extraction from oilfield brines inefficient and discouraging. In this study, we demonstrate a novel evaporation-based lithium extraction method using a twisted cellulose fiber crystallizer, which achieves evaporation rates three orders of magnitude higher (221 vs. 0.2 kg h-1 m-2) than traditional evaporation ponds, significantly reducing processing time to a few hours and saving land space. During the process, lithium concentration is enriched by 544 times, from 0.01 wt.% to 4.3 wt.%. Additionally, this process demonstrates high selectivity between Li+ and Na+ ions (~3523), presenting a potential game changer for lithium extraction from low-concentration brines.

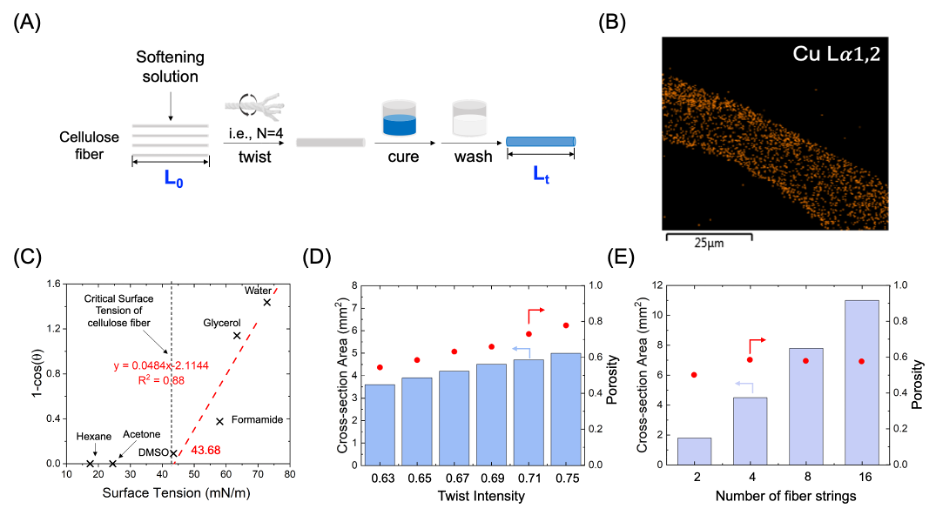

Characterizations of fiber crystallizer. (A) Fabrication process of fiber crystallizer. (B) EDX mapping detected a homogenous distribution of Cu on fabricated fiber crystallizer. (C) Free surface energy diagram for treated fiber crystallizers. (D) Porosity and cross-section area distribution for crystallizers with different twist intensities (TIs). (E) Porosity and cross-section area distribution for crystallizers fabricated with different number of fiber strings.

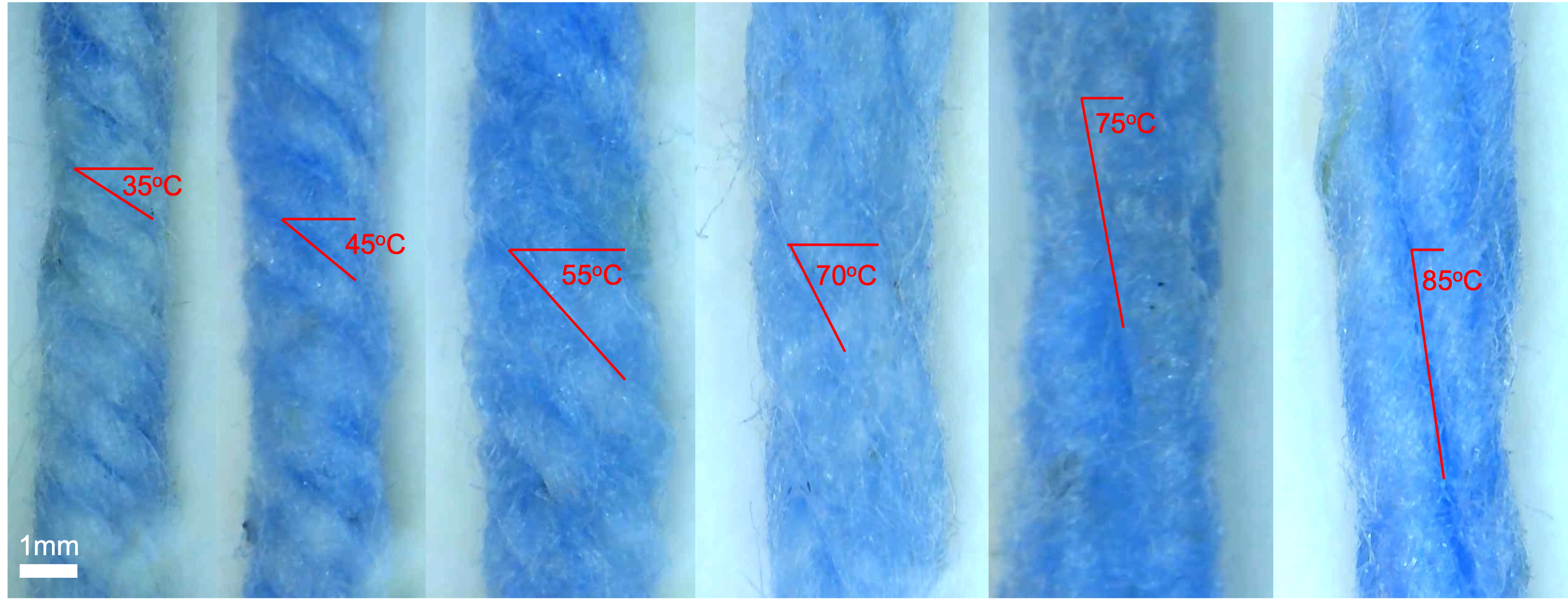

Crystallizers with different twist structures.

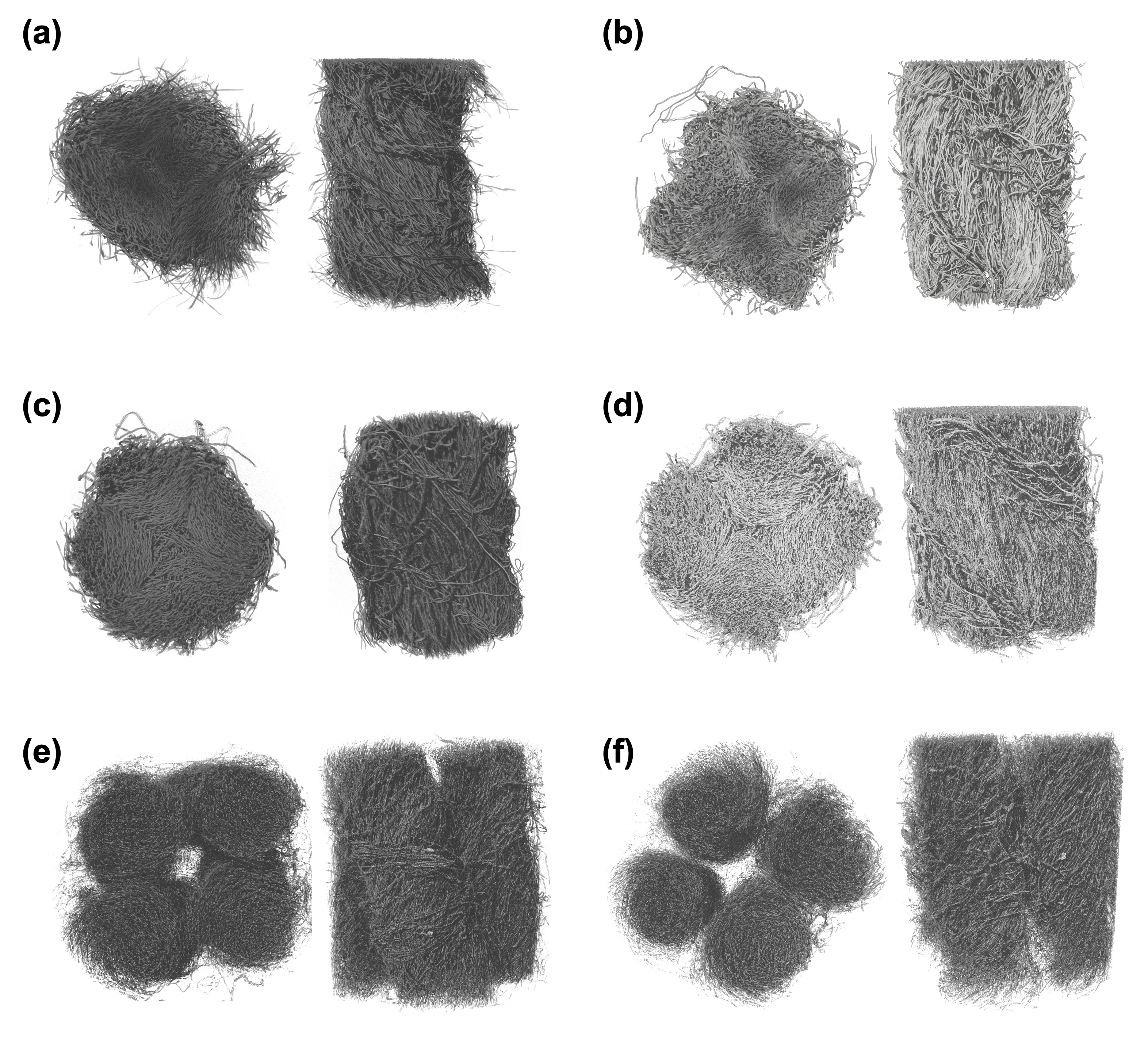

Crystallizers with different twist structures, 3D X-ray images.

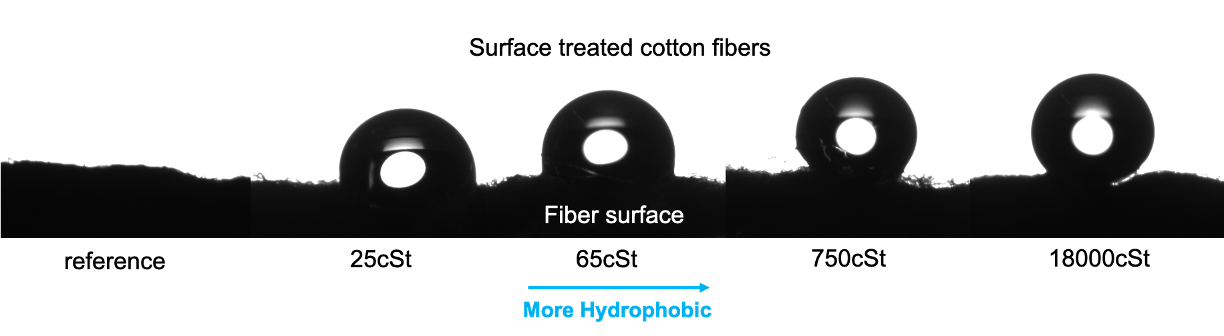

Crystallizers after surface treatment with different hydrophobicities.

Summary of lithium extraction performance and Li/Na selectivity.